I have been thinking of writing on complete Production Process in Microsoft Dynamics 365 for so long, so this is the first part of the series.

Now, in manufacturing process most important factor is cost, how we define the costing impact and how do we account this in financials. So, one of the major components for costing is “Cost group”. So, in this blog we will be uncovering Cost group configuration and its important.

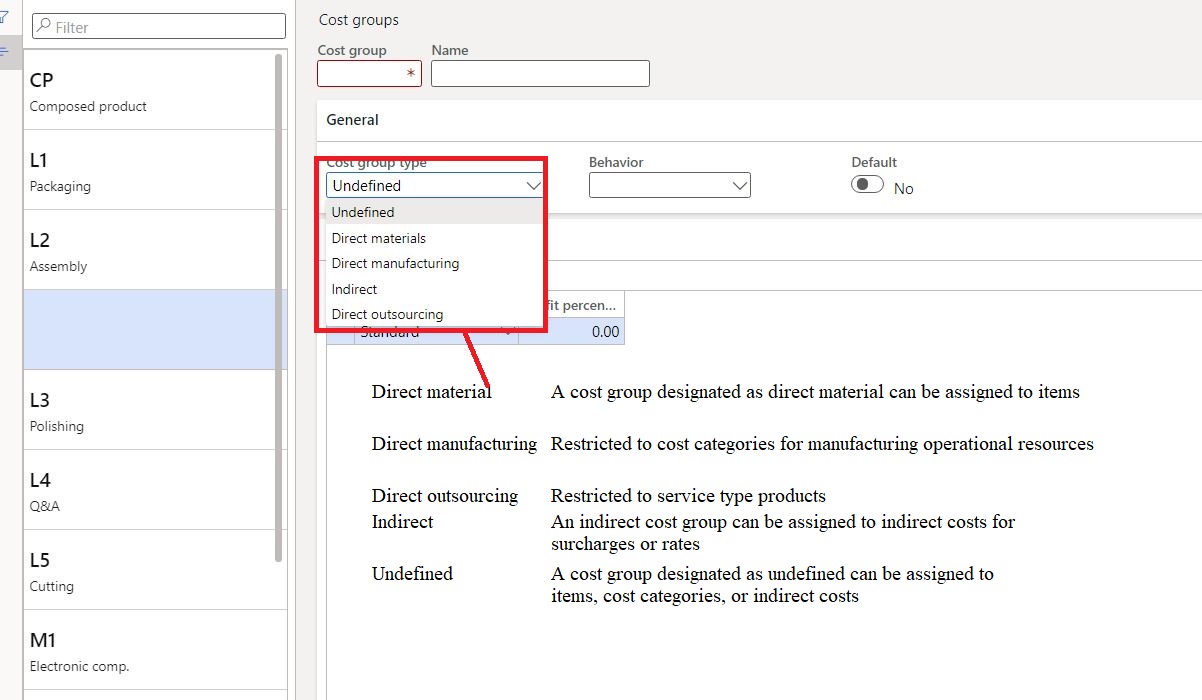

Cost group is the classification of the different types of cost component contributed to manufacturing process. It also defines the nature of the cost in manufacturing process. There are different types of cost groups we can define in system depends on the nature of the cost.

Example: Company says that they want to see the breakup of manufacturing cost of the finished goods by different types like raw material cost, packing cost, sub-contracting cost, labor cost, machine cost, overheads etc. All these different levels and components can be defined as cost group and can be associated with the costing sheet.

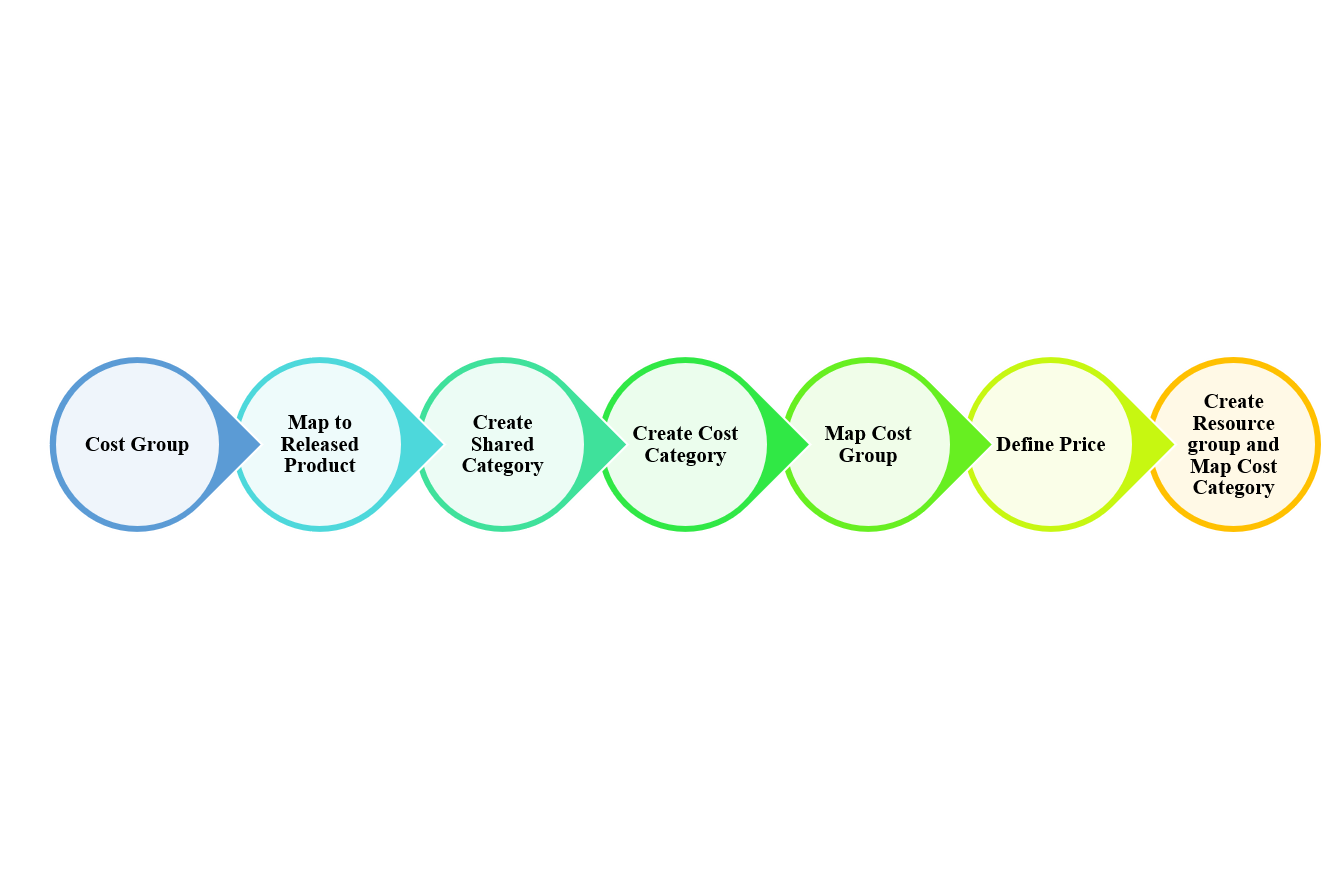

Step-1: Create Cost Group and enable Cost control.

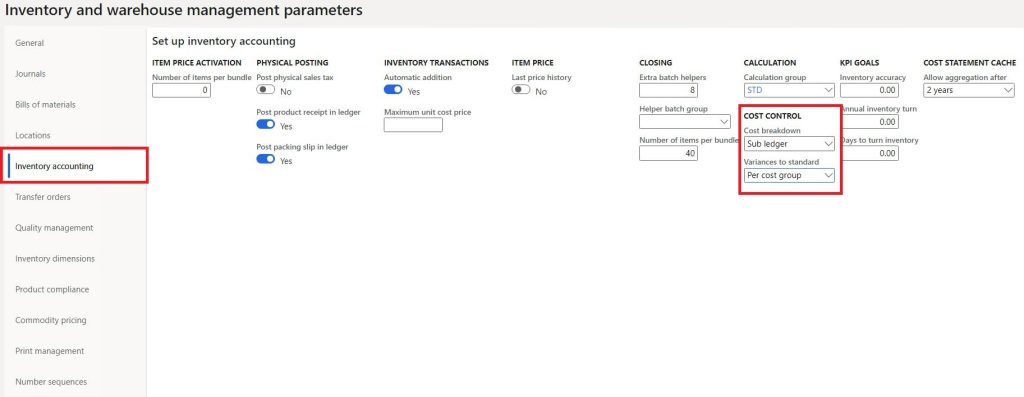

To analyse or configure different cost component, we need to enable the cost control in inventory parameters.

Inventory Management > Parameters > Inventory Accounting

Production Control > Setup > Route > Cost groups

Depending on cost visibility requirement you should create required cost groups for all different types of costs.

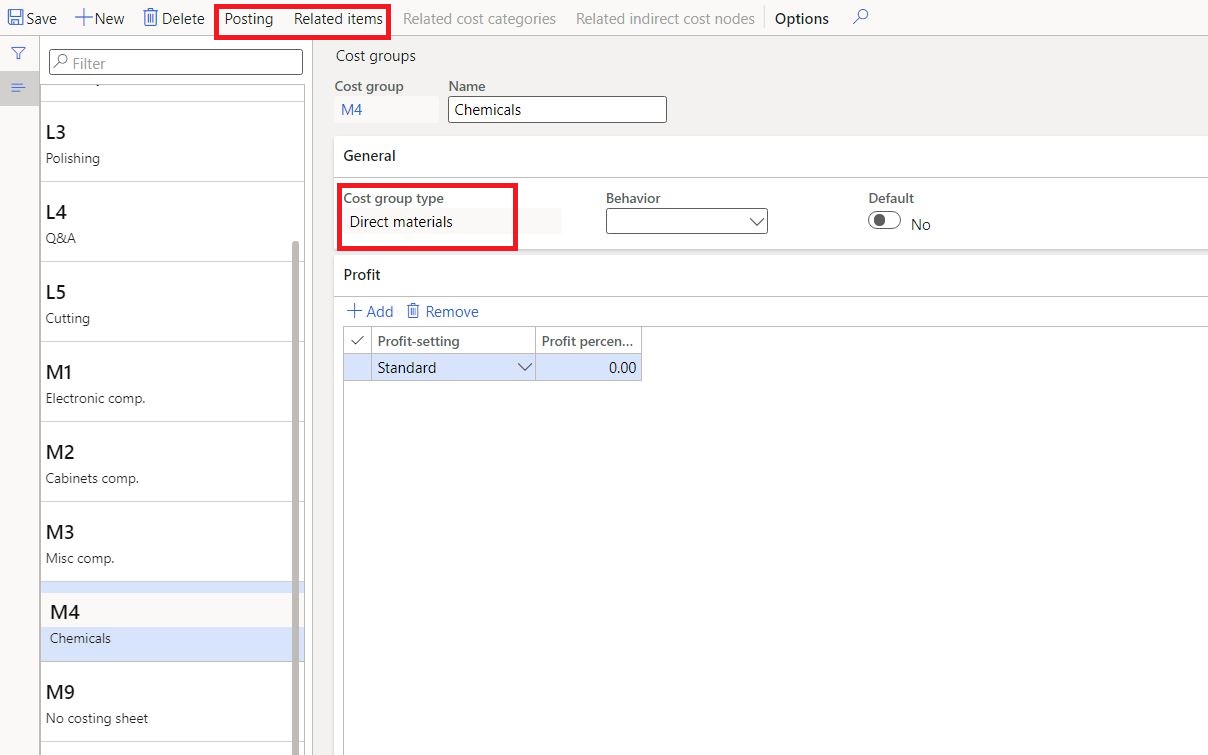

Step-2: Define Posting (Standard Cost)

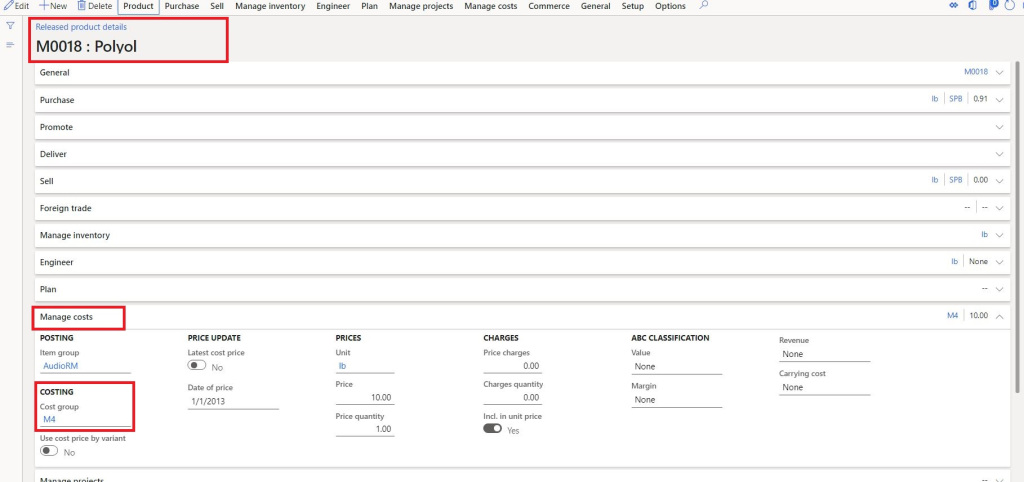

Step-3: Map Cost group to Released Products.

Released Products > Open and Edit Product > Manage Cost Fast tab

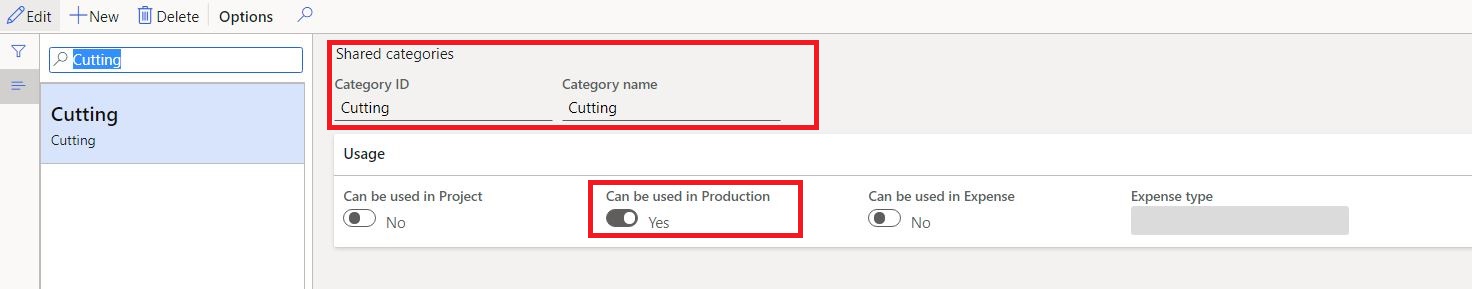

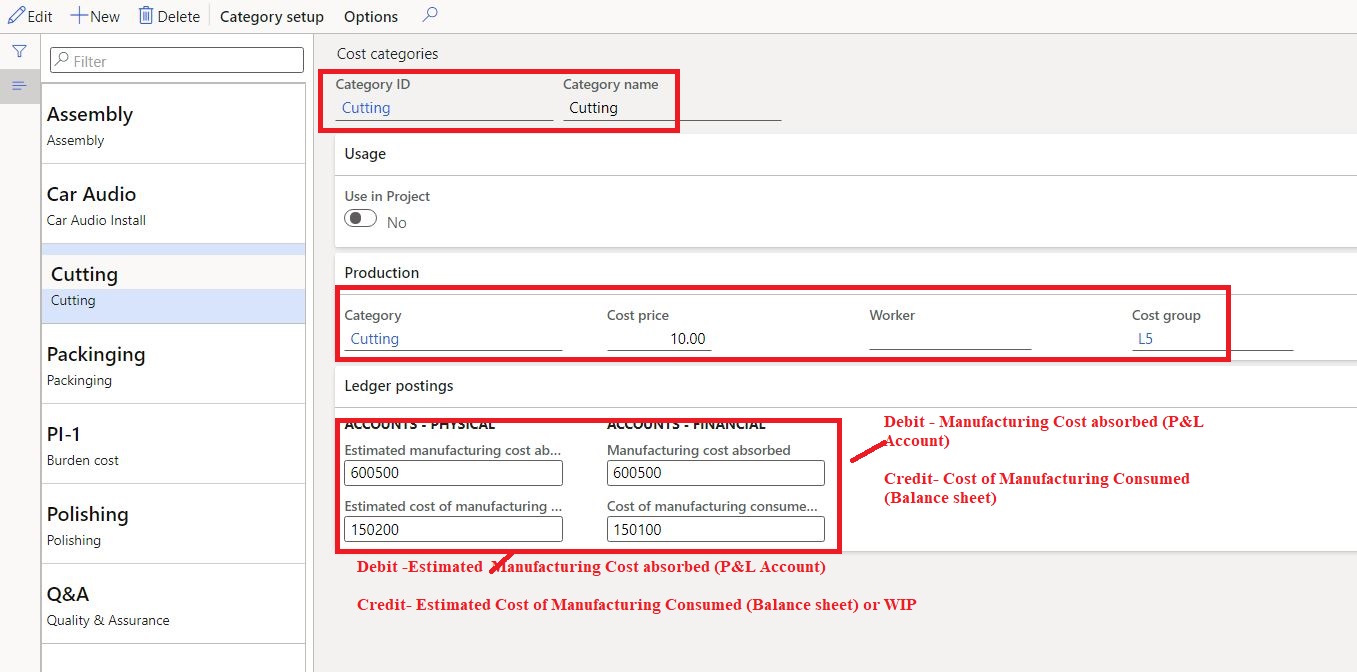

Step-4: Create Shared Category and Cost category

Here we can define the ledger posting for each cost category.

Cost categories apply to manufacturing environments that use routings. Cost categories are assigned to operations resources and routing operations to define hourly costs and segment cost contributions in a manufactured item’s calculated costs. That is, the cost groups that are assigned to cost categories classify manufacturing cost contributions by operation resources and the type of activity, such as setup and run time.

Each cost category has its associated cost records and an assigned cost group. Different cost categories are needed to support different production purposes.

- Assign different hourly costs by operations resource, such as different costs for various types of labour skills, machines, or manufacturing cells.

- Assign different hourly costs for the setup time or run time that is associated with a routing operation.

- Assign operations resource costs based on output quantity rather than hourly costs, such as the piece rates for paying labour.

- Provide cost group segmentation of cost contributions to a manufactured item’s calculated cost, such as segmentation of labour and machine costs.

- Provide the cost group basis for overhead calculation formulas, such as labour-related and machine-related overheads or overheads that are related to setup and run time.

Production Control > Setup > Route > shared Category / Cost Category

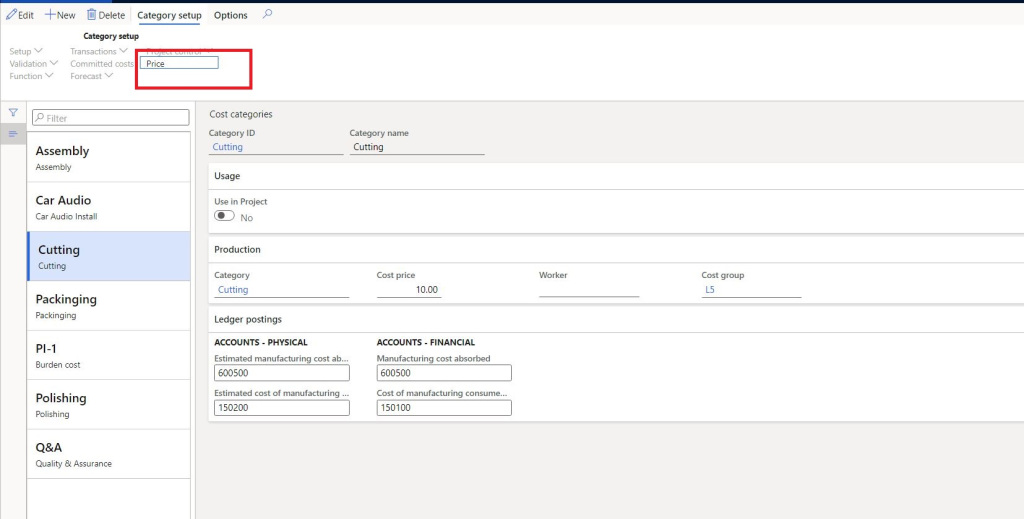

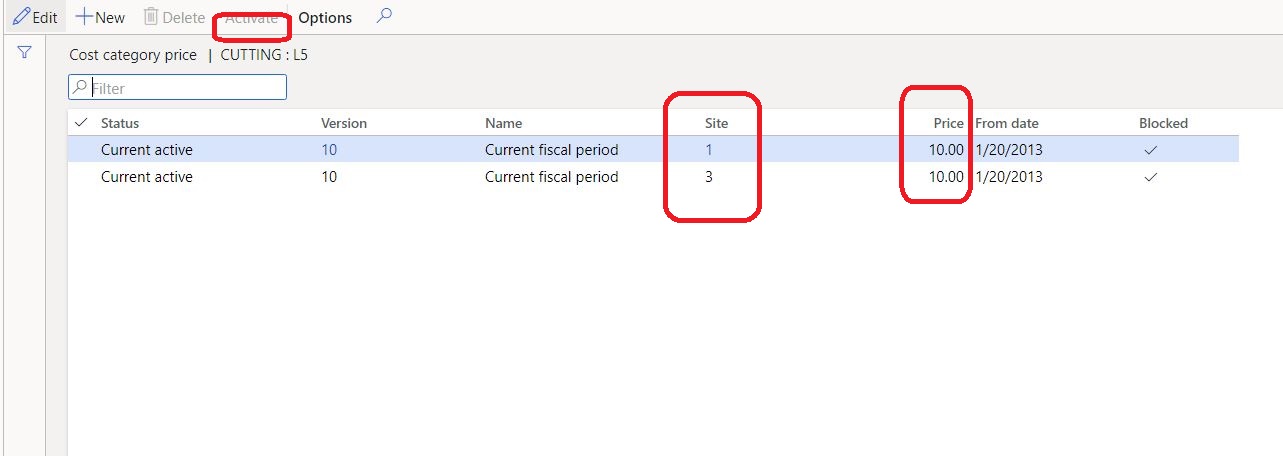

Step-5: Define Price for Cost Category

Once we defined cost categories and mapped with cost group, now we can define price for each cost category, now this can be defined organization level or site specific.

Production Control > Setup > Route > Cost Category > Price > New > Define price > Activate.

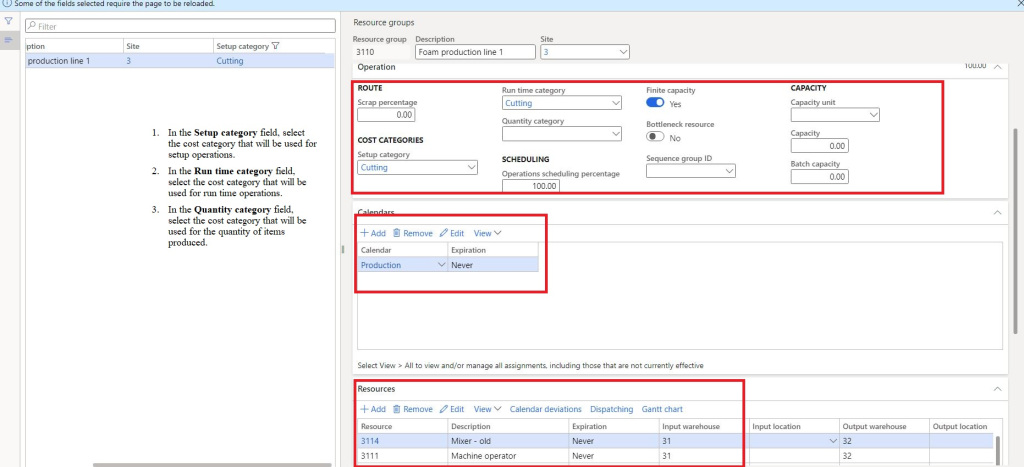

Step-6: Map Cost Category to Resource Group

A cost category can be assigned to the setup time, process time, and the quantity for a routing operation. When costs or cost group segmentation differ between setup and process time, for example, different cost categories should be defined and assigned to them. The selective usage of cost categories for setup time, process time, and quantity is determined by the route group that is assigned to an operation.

Production Control > Setup > Resources > Resource group

Note: This setup of mapping at resource group can be overridden by mapping cost category at “Resource or Operation level” as well.

Thank you !!! Keep reading and sharing !!!